Is Modular Construction the Secret to Faster, Cheaper Projects in 2025?

Written by NVAS Construction — Your Trusted General Contractor in Canton, Massachusetts

The construction industry in 2025 looks very different from what it did just a few years ago. Rising material costs, limited labor availability, and tighter project deadlines have builders and business owners rethinking how they approach construction.

At NVAS Construction, we’ve seen firsthand how modular construction is changing the game for developers across Massachusetts — offering faster build times, lower costs, and higher efficiency without sacrificing quality. But is it really the secret to faster, cheaper projects in 2025? Let’s find out.

What Is Modular Construction?

Modular construction is a building process where sections of a project — known as modules — are built off-site in a controlled factory environment. Once complete, these modules are delivered to the job site and assembled into the finished structure.

Unlike traditional construction, which happens step by step on-site, modular allows site work and fabrication to happen simultaneously, cutting project timelines dramatically.

For example, on a recent commercial job outside Boston, our team at NVAS Construction used modular framing to speed up delivery by nearly 40%. While the foundation was poured, the modules were being built and finished off-site — ready to stack as soon as the site work wrapped up.

Why Modular Construction Is Booming in 2025

The demand for faster and cost-efficient construction has never been higher. Across Massachusetts and the U.S., modular construction is gaining traction among developers, homeowners, and commercial clients alike. Here’s why:

1. Labor Shortages and Rising Costs

Skilled trades are in short supply across the state. Modular construction helps by reducing the number of on-site labor hours needed and minimizing weather-related delays — a big deal during unpredictable New England winters.

2. Advanced Technology

With AI-driven design software and precision manufacturing, modular builds in 2025 offer better accuracy, fewer mistakes, and almost zero material waste.

3. Sustainability and Green Building

More clients are asking for eco-friendly and energy-efficient construction. Modular fits perfectly with that vision — using fewer materials, reducing transportation waste, and supporting LEED-certified projects.

The Big Advantage: Faster and Cheaper Projects

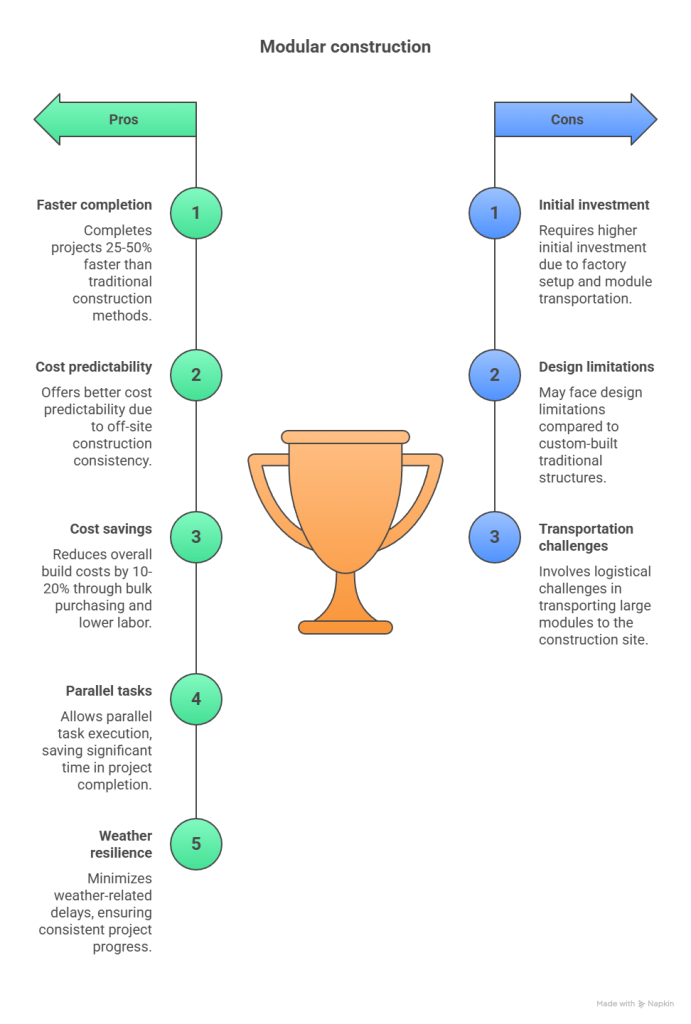

Speed That Saves Time (and Money)

Traditional construction projects in Massachusetts can take over a year to complete, depending on the complexity. With modular construction, many projects are completed 25–50% faster.

Because the modules are built in factories while the site is being prepared, both stages run in parallel. That means no waiting for one task to finish before starting another — a major time-saver for both residential and commercial builds.

Lower Overall Construction Costs

Modular projects bring better cost predictability. Since most of the work happens off-site, there are fewer delays, less rework, and more consistent pricing.

You save money through:

- Bulk material purchasing

- Reduced labor expenses

- Shorter project timelines (lower financing costs)

- Fewer weather-related setbacks

In many cases, modular projects can lower total build costs by 10% to 20%, which adds up quickly on large-scale developments.

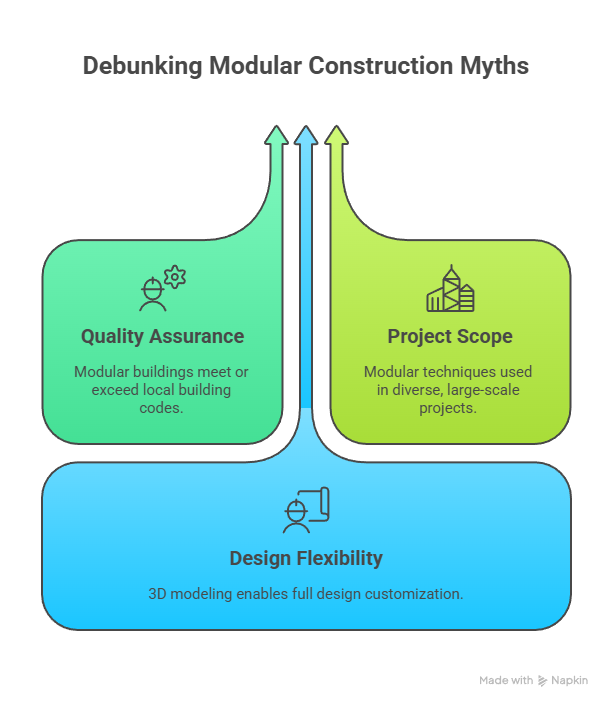

Common Myths About Modular Construction

Even with all its advantages, modular construction still faces a few misconceptions. Let’s clear those up:

Myth #1: “Modular buildings are low quality.”

Truth: Modern modular buildings meet — and often exceed — local building codes in Massachusetts. Factory precision ensures tighter tolerances and consistent craftsmanship.

Myth #2: “It’s only for small or temporary projects.”

Truth: Not anymore. Modular techniques are used in schools, hospitals, luxury homes, and high-end commercial projects across the country.

Myth #3: “You can’t customize modular designs.”

Truth: With today’s 3D modeling and BIM technology, modular construction allows for full design flexibility — from custom facades to high-end finishes.

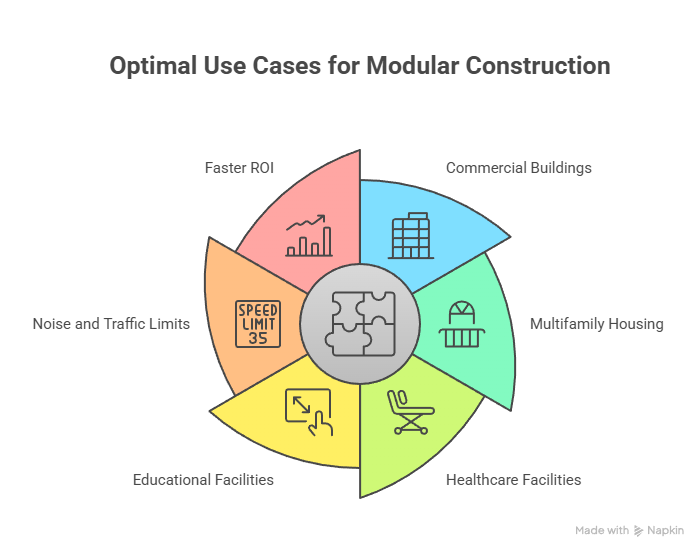

When Modular Construction Makes the Most Sense

Modular construction isn’t a one-size-fits-all solution, but it works extremely well for:

- Commercial buildings (offices, hotels, retail)

- Multifamily housing and apartment complexes

- Healthcare and educational facilities

- Projects in areas with strict noise or traffic limits

- Developers seeking faster ROI

For Massachusetts developers, where project timelines and labor costs are critical, modular offers a clear competitive edge.

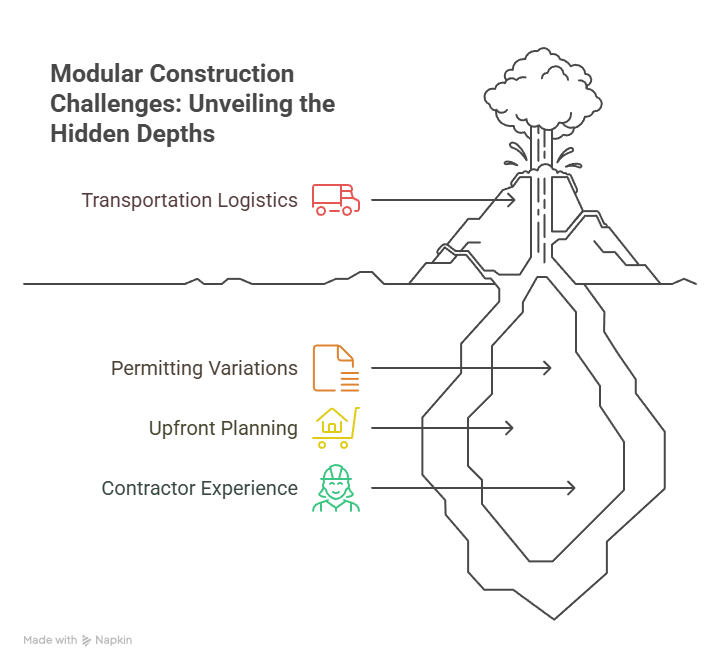

Challenges to Be Aware Of

No construction method is perfect — and modular comes with its own set of challenges:

- Transportation logistics can be complex, especially for large modules.

- Permitting varies by city and town, so it’s crucial to work with an experienced local contractor.

- Upfront planning is essential since modular projects require tight coordination between design, engineering, and assembly teams.

At NVAS Construction, our experience as a general contractor in Canton, MA helps clients navigate these challenges smoothly — ensuring every modular build meets code, budget, and timeline.

A Real Example: Modular Done Right

One of our recent projects involved modular framing for a multi-unit residential development near Canton. By combining factory-built modules with on-site expertise, we reduced project duration from 14 months to under 9 months.

The client saved significantly on financing costs, achieved early occupancy, and reduced material waste by nearly 20%. That’s the power of modular done right — when planned and managed by an experienced general contractor.

The Future of Modular Construction in Massachusetts

Looking ahead, modular construction in Massachusetts will only continue to grow. With improvements in technology, sustainability, and project management tools, more homeowners and developers are making the shift.

At NVAS Construction, we believe modular construction isn’t just a passing trend — it’s a smarter, faster, and greener way to build for the future.

FAQs About Modular Construction in 2025

1. How much does modular construction cost in Massachusetts?

Costs vary depending on size and materials, but most modular projects range from $150 to $250 per square foot — about 10–20% less than traditional builds.

2. How long does a modular project take?

A typical modular build in 2025 can be completed in 6–9 months, depending on project type and complexity.

3. Are modular buildings durable in New England weather?

Yes. Modular buildings are built to meet or exceed local building codes and are designed to withstand transport and assembly — making them highly durable and weather-resistant.

4. Can modular construction be customized?

Absolutely. From floor plans to finishes, modular projects can be tailored to match your brand, style, or functional needs.

Is Modular the Secret to Smarter Building?

In 2025, modular construction isn’t just about building faster — it’s about building smarter. When managed by the right team, modular can deliver top-quality results with lower costs, faster timelines, and sustainable outcomes.

If you’re a developer, business owner, or homeowner in Massachusetts looking to break ground this year, modular construction could be the key to completing your project on time and under budget.

Build Smarter with NVAS Construction

Thinking about a modular construction project in 2025?

At NVAS Construction, we bring years of hands-on experience as a general contractor in Canton, Massachusetts, helping clients design, plan, and execute modular builds that save time and money — without cutting corners.

👉 Contact NVAS Construction today to schedule a consultation or request a project estimate. Let’s build something better, faster, and smarter together.